The Living Systems Laboratory is located at the former historic Fisherville Mill in South Grafton, Massachusetts, immediately downriver of the confluence of the Quinsigamond and Blackstone Rivers. The Blackstone River flows for 48 miles from Worcester, Massachusetts, to Providence, Rhode Island. The Blackstone River corridor is known as the birthplace of the American Industrial Revolution. In 1986, the Blackstone River Valley was designated as one of the first National Heritage Corridors. The Blackstone Canal runs through both the north and south sections of the Fisherville Mill site. A 1999 fire completely destroyed the Fisherville Mill, but the Canal, which is an important historic artifact, is largely intact.

After the1999 fire, the EPA, under an “Emergency Response Action”, and the Massachusetts State DEP spent several million dollars treating trichloroethylene (TCE) pollution at the site using various means, including in-situ chemical oxidation and groundwater collection and treatment. The U.S. Environmental Protection Agency (EPA) later awarded the Town of Grafton a $671,000 grant to design, construct and operate an innovative ground water, stormwater and river water treatment and improvement park consisting of several integrated elements. As part of this project, John Todd Ecological Design (JTED) was contracted by the Town to design and implement a restoration plan for the Blackstone River using an engineered ecosystem utilizing the canal trench and the existing infrastructure remaining from the destroyed Fisherville Mill.

Aerial view of the Fisherville Mill site, south of the confluence of the Blackstone and Quinsigamond Rivers.

The overall purpose of the project was to treat stormwater and contaminated groundwater flowing into the Canal. A particular focus was on removal of the primary legacy pollutant, #6 fuel oil, also known as Bunker C oil, a high-viscosity residual oil, that leaches into the groundwater and the canal from several leaking underground storage tanks.

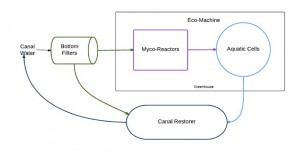

JTED constructed a Canal Restorer “Eco-Machine” to reduce Bunker C oil in the Blackstone River Canal. The principle of the design for the project was to develop a system with complex ecology that, through design and natural selection, would evolve to maximize diverse biological processes for contaminated water and sediment treatment. There are three general components to the system. First, contaminated water from the Canal is drawn through the microbial “Bottom Filters.” The Bottom Filters are submersed in the middle of the Canal and draw between 500 to 1000 gallons of water per day. The water is then pumped to the Eco-Machine, which is housed in a greenhouse that has two sub-components: the “Myco-Reactors” and the “Aquatic Cells.”

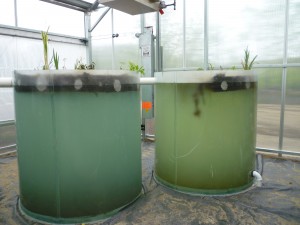

Contaminated water is dispersed into the Myco-Reactors, which contain microbial communities intended to break down hydrocarbons and other pollutants. The water from the Myco-Reactors next enters the Aquatic Cells which is a series of six 700 gallon tanks that contain plants, animals and microbes in the tanks.

After treatment in the Eco-Machine, water is dispersed on the “Canal Restorer” which is a floating raft system. The Canal Restorer has native plant species that establish root systems in water column of the Canal. The Canal Restorer and Bottom Filters also operate as an independent loop. All three components are part of one system with each having a supporting role, with the overall goal to have the system becoming self-sustaining.